About Titanium Vacuum Device

The vacuum devices manufactured by Seiwa are mainly used in experimental instruments which need "vacuum" environments, such as particle accelerators.

Seiwa has until now provided various vacuum devices to research laboratories and universities which play an important role as advanced technology developer, such as High Energy Accelerator Research Organization (Inter-University Research Institute Corporation), National Institute of Advanced Industrial Science and Technology, Japan Atomic Energy Agency, The University of Tokyo and University of Tsukuba.

Seiwa's quality and reliability are highly praised.

Seiwa also designs, manufactures and customizes specific products suitable for specialized experiment requirements, and always supports researchers to realize their "wants".

With titanium, the radiation level is lowered in a few days and the higher turnover rate of experiment can be reached.

With stainless steel, a few weeks of interval are reportedly required, with titanium, a few days. Because it greatly depends on the exposure condition and radiation level, please contact us for the matter.

A half weight of stainless steel. The usability for researchers is a key factor to improve the efficiency of research.

Titanium has superior high-temperature strength, though stainless steel has higher hardness in general.

With titanium, experiment intervals can be shortened to a few days from a few weeks.

Stainless steel, mainly, has been used for the experiments with radiation in order to maintain vacuum in a clean environment.

However, stainless steel tends to hold radiation inside, namely easily radioactivated. Therefore, with stainless steel a researcher needs a few weeks until radiation level lowered to obtain experimental results.

Design -> Machining-> Welding -> Assembly -> Control -> Site installation. (The operation within a managed area acceptable)

Design from a rough sketch or a specification form, even from a scratch, can be accepted.

Precision Machining with Machining Center, CNC lathe.

5-axis machining used with 3D CAD/CAM. Highly skilled engineers work manually.

Vacuum welding technology -> Welding technology specialized for vacuum chamber.

Welding titanium or aluminum acceptable.

-

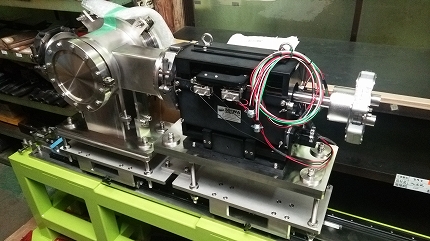

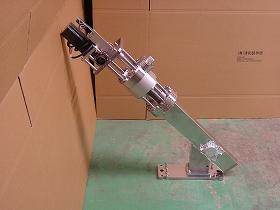

Trestle for Driving All Titanium Chamber with Bellows

Trestle for Driving All Titanium Chamber with Bellows

Used in J- PARC MR -

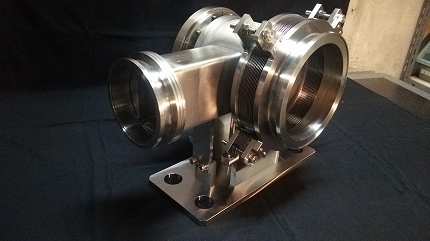

All Titanium Chamber with Bellows

All Titanium Chamber with Bellows

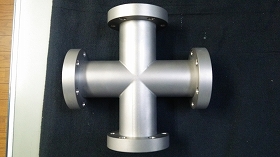

Leakage Rate 1.0X10^-11Pa・m^3  Titanium Cross Pipe

Titanium Cross Pipe

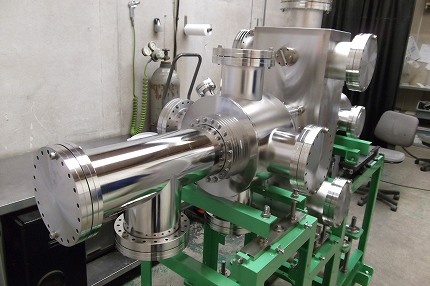

ICF70 X 4 Titanium Rectangular Chamber

Titanium Rectangular Chamber Titanium ICF Flange

Titanium ICF Flange

ICF70・ICF114 Titanium Hexagonal Pole

Titanium Hexagonal Pole

Milling Product Titanium Machined Product

Titanium Machined Product

Wire and Milling Product

-

Stainless Steel (SUS304) Rectangular Chamber (690X1830.6X2007)

Stainless Steel (SUS304) Rectangular Chamber (690X1830.6X2007)

Rectangular Chamber Internal Partition -

Stainless Steel (SUS316L) Rectangular Chamber (620X1050X1084)

Stainless Steel (SUS316L) Rectangular Chamber (620X1050X1084)

with Φ780 Flange and Linear Feedthrough -

IEC152 Special Chamber

IEC152 Special Chamber

ICF152 X 5 Ports・ICF70 X 6 Ports -

CT Monitor

CT Monitor -

Linear Feedthrough

Linear Feedthrough -

Linear Feedthrough (2)

Linear Feedthrough (2) -

Beam Position Measuring Device

Beam Position Measuring Device -

Beam Position Monitor

Beam Position Monitor -

Short Pipe with Ceramics

Short Pipe with Ceramics -

Gate Valve with Bellows

Gate Valve with Bellows

-

Pure Aluminum Mirror

Pure Aluminum Mirror

External Diamiter Φ300 -

5N(99.999%)Aluminum Flange

5N(99.999%)Aluminum Flange

-

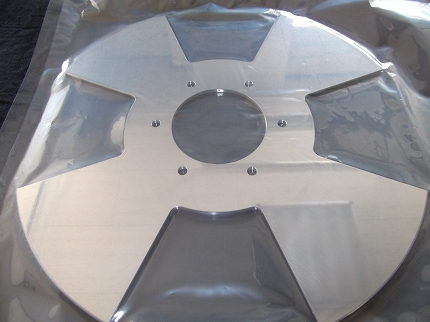

Chopper Disk

Chopper Disk